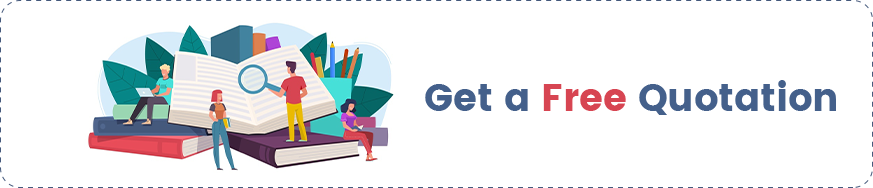

Wire Straightening Cutting Machine For Iron Wire

Wire Straightening Cutting Machine For Iron Wire has CE&SGS certification, ISO1990 Quality system certification, and so on...Good quality and professional pre-sales, and after-sales service for you.

Product Description

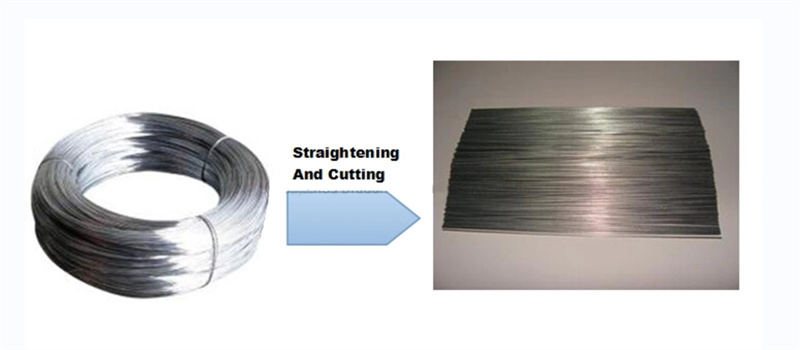

Wire straightening and cutting machines for iron wire come in various sizes and capacities, ranging from small tabletop machines for low-volume production to large automated machines for high-volume production. They can handle different types of iron wires, including mild steel wire, stainless steel wire, and galvanized wire, with varying diameters and lengths.

These Wire straightening and cutting machines are commonly used in applications where straight and accurately cut wire is required, such as in the production of wire mesh, wire ropes, wire hangers, and reinforcement bars for concrete structures. They are efficient, precise, and labor-saving, helping to improve productivity and reduce production costs in wire processing operations.

Straightening and Cutter Galvanized Wire Wire Cutting and Straightening Machine Iron Straightening Machine Straightener Wire Machine

This device can be suitable for all kinds of metal wire straightening cutting, surface, no scratches, cutting length error of 0.2-0.5 mm, the cutting length range is 80mm to 6000mm. Human-machine incorporate touch screen control system, can save manpower for the customer. Company's main range of wire 1 mm to 5 mm can be customized, fastest of up to 150 meters per minute,available for copper, iron, aluminum, gold, silver, stainless steel, high carbon steel and plastic coated wire, metal wire.If you want faster speed, please contact customer service.If you are concerned about the straightening effect, we can provide free proofing.

A wire straightening and cutting machine for iron wire is a mechanical device used to straighten and cut iron wires into desired lengths with precision. It is commonly used in industries such as construction, manufacturing, and wire processing.

The machine typically consists of the following components:

1.Wire feeding system: This system feeds the coiled iron wire into the machine. It may include a wire decoiler, wire straightener, and wire feeding rollers to ensure smooth and continuous feeding of the wire.

2.Straightening system: This system consists of straightening rollers or plates that are designed to straighten the wire as it passes through them. The number and configuration of the straightening rollers or plates may vary depending on the desired level of straightness required for the wire.

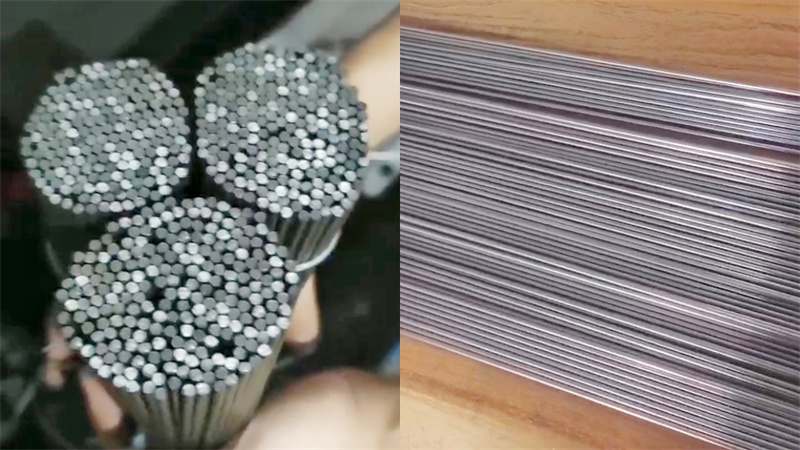

3.Cutting system: This system includes a cutting mechanism that is designed to accurately cut the straightened wire into the desired lengths. The cutting mechanism may use various methods such as shear cutting, guillotine cutting, or rotary cutting depending on the specific design of the machine.

4.Control system: This system includes controls for adjusting the speed of the wire feeding system, the straightening system, and the cutting system. It may also include features such as length measurement and batch counting for precise and efficient wire cutting.

5.Safety features: Wire straightening and cutting machines typically include safety features such as guards, emergency stop buttons, and sensors to ensure safe operation and prevent accidents.

Configuration parameters of Wire Straightening Cutting Machine For Iron Wire:

1 two servo motors, 1.5 kw traction and 1:10 planetary reducer, cut off 1.5 kw,

2 cut off the PLC touch screen electronic CAM system,

3 servo motor brand, servo motor

4 fuselage length 1850mm wide 780mm total height 1300mm.It weighs about 498 kilograms.

5 the total weight of the automatic spreader is 90kg.

6. The control mode includes inverter analog control system,

7. Minimum diameter: 250mm; maximum diameter: 500mm;

8 the weight of the spreader is about 90kg"

|

Type and wire diameter: |

QP-φ0.2-1mm |

QP-φ1-6mm |

QP-φ7-12mm |

|

Cutting range: |

10mm – 99999mm |

||

|

Max cutting speed: |

200pcs/min |

||

|

Wire feeding speed: |

20-60m/min |

20-80m/min |

20-60m/min |

|

Length error: |

±0.2mm |

||

|

Wire material: |

Common carbon steel wire and stainless steel wire |

||

|

Accessories: |

Withdrawable wire rack, Movable receiving pocket, Recommended automatic wire rack for lines above 3.0 |

||

|

Feeding stand: |

1000*300*150 |

||

|

Feeding motor: |

2.0kw servo motor |

||

|

Straightening motor |

Custom adjustable speed motor 3KW/2880r |

||

|

Cutting shear motor: |

2.8KW Cut off servo motor |

||

|

Rail module: |

Nextron |

||

|

Number of feeding rollers: |

2 group (4 pairs rollers) |

||

|

HMI: |

7 inch touch screen |

||

|

Number of straightening rollers: |

8 pcs |

||

|

Material of shear: |

Cr12 Steel, partly made by Nextron |

||

|

Electric box brand: |

Relay—IDEC, |

||

|

Measurement(length*width*height) |

1700*700*1350(mm) |

||

Key Features of Wire Straightening Cutting Machine For Iron Wire:

●Precision Straightening: The Wire Straightening Cutting Machine For Iron Wire can handle wire diameters ranging from 2mm to 12mm, making it suitable for different wire sizes and types.

●Efficient Cutting: The wire straightening cutting machine for iron wire is equipped with a powerful cutting mechanism that allows for efficient and clean wire cutting. It can cut wires to the desired length with high speed and accuracy, increasing productivity and reducing labor costs.

●Durable Construction: The wire straightening cutting machine for iron wire is built with a robust frame and high-quality components, ensuring durability and long-term reliability. It is designed to withstand heavy-duty usage in industrial environments, minimizing downtime and maintenance costs.

●User-Friendly Design: The wire straightening cutting machine for iron wire features a user-friendly control panel that allows operators to easily set the desired wire length, cutting speed, and other parameters. It also includes safety features such as emergency stop buttons and protective guards, ensuring safe and efficient operation.

●Versatility: The wire straightening cutting machine for iron wire is a versatile machine that can handle various types of iron wire, including round, square, and rectangular wires. It is suitable for a wide range of wire processing tasks, such as wire mesh production, wire forming, and wire fabrication.

●High-Speed Operation: The wire straightening cutting machine for iron wire is capable of high-speed wire straightening and cutting, with a maximum speed of up to 100 meters per minute. This allows for efficient and rapid wire processing, increasing productivity and reducing production time.

●Customizable Options: The wire straightening cutting machine for iron wire can be customized to suit specific requirements, such as additional features or specialized wire processing capabilities. QIPANG, the manufacturer of wire straightening cutting machine for iron wire, offers customization options to cater to different customer needs.

Benefits of Wire Straightening Cutting Machine For Iron Wire:

◆Increased productivity and reduced labor costs due to high-speed operation

◆Precise and accurate wire straightening and cutting for consistent results

◆Durable and robust construction for long-term reliability

◆User-friendly design for easy operation and minimal downtime

◆Versatile and customizable options to suit different production needs

Advantages of Wire Straightening Cutting Machine For Iron Wire

1. We have CE&SGS certification ,ISO1990 Quality system certification ,so on...

2. Good quality and professional pre - sales, after - sales service.

3.13 years of development, manufacturing and marketing experience, the main customers are: North America (United States, Canada, Mexico), Europe (Italy, Britain, France, Poland, Netherlands), Southeast Asia, etc.

4. Flexible development and customization CEM COM.

5. Excellent consulting team covering the world.

6. Fast spare parts distribution and sufficient inventory.

QIPANG wire straightener series

Packing:

The wire straightening cutting machine for iron wire is a reliable and efficient wire straightening and cutting machine designed for processing iron wire. With its precision straightening, efficient cutting, durable construction, user-friendly design, versatility, high-speed operation, and customizable options, it is an ideal solution for businesses looking to optimize their wire processing operations. Whether it's for wire mesh production, wire forming, or wire fabrication, the wire straightening cutting machine for iron wire offers superior performance and reliable results.