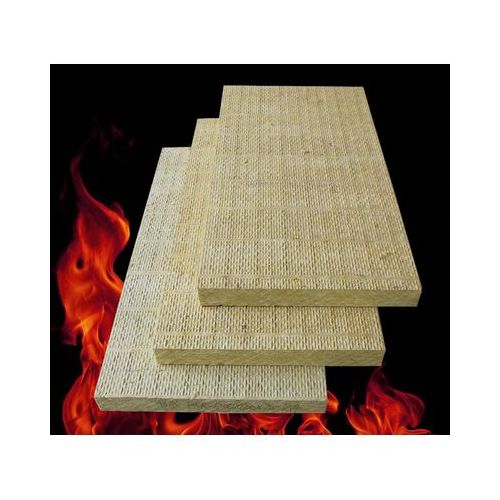

Rockwool fiber board products

Product Description

Payments:L/C, D/P, T/T, Western Union, Paypal

Delivery:by sea

Origin:china

Packing:plybag

Inspection:SGS TUV AND OTHER THIRD-PARTY INSPECTION

Samples:Free

ROCKWOOL FIBER BOARD

Haimo rock wool insulation board is high strength board, used high-quality basalt ore as main raw material, through the high temperature melting and high speed centrifugal wire into fiber, with three dimensional method advanced production technology, added a few binding agent, shaped by thermal curing. Products are widely applied to building exterior wall insulation, roof insulation of curtain wall, industrial and civil building, compound core board, and equipment and pipeline insulation of marine bulkhead , fire door core board and all kinds of industrial or shipbuilding equipment.

rock wool for industry

high temperature resistance

good hydrophobicity

high corrosion resistance and low thermal conductivity

provide the highest level of protection against heat and energy loss in the field of petrochemical, power plants, industrial tanks and other industrial equipment

to avoid fire, noise and other harmful effects.

rock wool for building

Exterior wall insulation thin plastering system is a kind of non-bearing insulation structure, consists of insulation layer,

protective layer, fixed materials (adhesives, auxiliary fixings, etc.), and is fixed in the external surface of exterior wall,

with performance of fire safety, heat insulation, waterproof, anti-cracking, anti-wind pressure and durability.

Typical Parameters

Properties | Unit | Density | |||

80 | 100 | 120 | 140 | 150 | 160 |

Combustion performance | -- | Class A1 non-combustion | |||

Compression Strength(10%deformation) | kPa | ≥40 | |||

Hydrophobic rate | % | ≥98.0 | |||

Melt temperature | \u2103 | >1000 | |||

Acidity ratio | -- | ≥1.8 | |||

Moisture absorption rate | % | ≤1.0 | |||

Thermal conductivity(average 25\u2103) | W(m.k) | ≤0.048 | ≤0.040 | ||

Dimensional stability | % | ≤1.0 | |||

Water absorption(Partial Immersion) | Kg/m2 | Short term(24h)≤1.0 Long term(28d)≤3.0 | |||

Thickness tolerance | mm | ±2 | ±3 | ||

Right angel degree of deviation | mm/m | ≤5 | |||

Planeness tolerance | mm | ≤6 | |||

properties after ignition-burning | Shrinkage percentage | % | (750\u2103,0.5h)≤8 | ||

Mass loss rate | % | (750\u2103,0.5h)≤10 |