Conveyor Rubber Roller

Conveyor rollers with rubber coatings enable more friction between the roller and the driving belt.

Product Description

Rubber Rollers: A Comprehensive Guide to High-Quality Industrial Solutions

Introduction

Welcome to our comprehensive guide on rubber rollers, your ultimate resource for high-quality industrial solutions. At Boye Fengyuan Transportation Machinery Manufacturing Co., Ltd., we specialize in providing top-notch rubber rollers designed to meet the diverse needs of various industries. With our extensive expertise and commitment to excellence, we aim to offer an informative and engaging article that outranks other websites and provides you with valuable insights. Let's delve into the world of rubber rollers and explore their applications, benefits, and key considerations.

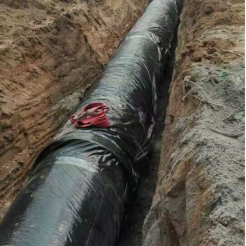

Rubber casting idler, the rubber is directly vulcanized on the surface of the steel pipe, with high elasticity, wear resistance, corrosion resistance, waterproof, impact resistance and other properties, and is widely used in various occasions. The service life of the rubber idler is much longer than that of the traditional idler, and the new rubber can be replaced after the old rubber is worn out.

Conveyor rollers may be created from various materials like plastic, aluminum, or steel. In order to improve the grip of conveyor rollers that are commonly built from these materials and to provide additional protection from goods slipping during the manufacturing process, many rollers use a rubber coating specifically designed for such rollers. Other conveyor rollers are made directly with rubber rollers.

Conveyor rollers with rubber coatings enable more friction between the roller and the driving belt. This is extremely helpful where there would othewise be belt slippage. Additionally, a non-marking rubber coating can be utilized to prevent marking where the product is likely to be easily marked by accident.

Specification

| Model NO. | Customized PU rubber conveyor roller | Materials | Rubber Coat,Metal Cores |

| Installation | Turning | Package | According to Customers′ Requirements |

| Hardness | 30 up to 90 Shore a and D | Transport Package | Carton Case or According to Customer Requirements |

| Type | Various | Trademark | Customized |

| Specification | Standard and Custom Services | HS Code | 8431390000 |

| Origin | China | Production Capacity | 50, 000 PCS/Year |

How Conveyor Rollers Work

The conveyor roller helps to hold the conveyor belt in place. The conveyor belt has an outward segment and a return section because it makes an unending loop around pulleys at the location where the materials are fed onto the belt, or feed point. The conveyor belt's job is to move the goods to a discharge point, where these items come off the belt once more.

The upper, or carry, section refers to the portion of the conveyor belt that faces outward and moves with the material from the feed point to the discharge point. From the discharge point to the feed point, the bottom part, or return section, goes backward devoid of any material. At various points, the conveyor rollers support and direct the conveyor belt.

Applications of Rubber Rollers

Rubber rollers find application in a myriad of industries, playing a crucial role in enhancing productivity and efficiency. Some common applications include:

1. Printing Industry: Rubber rollers are integral components in printing presses, where they aid in precise ink transfer and ensure uniform print quality.

2. Conveyor Systems: Rubber rollers are used in conveyor systems to facilitate the movement of materials along the production line, providing excellent traction and reducing slippage.

3. Packaging Industry: Rubber rollers are utilized in packaging machinery to guide, support, and apply pressure during packaging processes, ensuring accurate and consistent results.

4. Textile Industry: In textile manufacturing, rubber rollers help control tension, guide fabric movement, and apply dyes or chemicals evenly onto the fabric.

5. Industrial Machinery: Rubber rollers are employed in various industrial machinery, such as laminators, embossing machines, laminating machines, and more, to facilitate smooth material processing.

Benefits of Rubber Rollers

Rubber rollers offer several key benefits that make them indispensable in numerous industrial applications. Let's explore some of these advantages:

1. Excellent Traction: Rubber rollers provide exceptional grip and traction, allowing efficient material transfer and reducing the risk of slippage or misalignment.

2. Shock Absorption: The inherent resilience of rubber helps absorb shocks and vibrations, safeguarding delicate materials and sensitive components from damage.

3. Chemical Resistance: Rubber rollers can be customized with chemical-resistant properties, making them suitable for handling corrosive substances or environments.

4. Noise Reduction: Rubber rollers dampen noise generated during material handling, creating a quieter working environment and minimizing disturbances.

5. Versatility: Rubber rollers can be tailored to specific applications, offering a wide range of hardness, durometer, surface finishes, and other customizable features.

Key Considerations for Selecting Rubber Rollers

Choosing the right rubber rollers for your specific requirements is crucial to ensure optimal performance and longevity. Consider the following factors during the selection process:

1. Material Compatibility

Evaluate the compatibility of the rubber roller material with the substances it will come into contact with during operation. Different materials offer varying levels of resistance to chemicals, oils, solvents, and abrasives. Ensure the selected rubber roller can withstand the intended environment without compromising performance or durability.

2. Roller Size and Geometry

The size and geometry of the rubber roller should align with your application requirements. Consider factors such as diameter, length, core design, and surface patterns to ensure proper material handling, traction, and guidance.

3. Load Capacity and Weight Distribution

Determine the load capacity of the rubber roller to ensure it can handle the weight and pressure exerted during operation. Additionally, consider the distribution of the load across the roller surface to avoid uneven wear or damage.

4. Hardness and Durometer

The hardness and durometer of the rubber roller impact its ability to provide grip, absorb shocks, and resist wear. Choose the appropriate hardness level based on the application's demands and the desired amount of compression and flexibility.

5. Surface Finish

The surface finish of the rubber roller plays a crucial role in the quality of material handling. Smooth surfaces are ideal for delicate materials, while textured or grooved surfaces offer enhanced traction for challenging applications.

6. Customization Options

Partner with a reputable manufacturer like Boye Fengyuan that offers customization options for rubber rollers. This allows you to tailor the roller's specifications to your unique requirements, ensuring optimal performance and maximum productivity.

We look forward to working with you!

In conclusion, rubber rollers are indispensable components in various industries, facilitating smooth material handling, transferring, and processing operations. Their versatile applications, coupled with the numerous benefits they offer, make them essential for enhancing productivity and efficiency. When selecting rubber rollers, consider factors such as material compatibility, roller size and geometry, load capacity, hardness, surface finish, and customization options. By prioritizing these considerations and partnering with a trusted manufacturer like Boye Fengyuan, you can ensure you have the perfect rubber rollers for your specific needs. If you want to know more details, please contact us by email.