Extruder Screens & Packs

Extruder Screens & Packs

Product Description

What is an extruder screen?

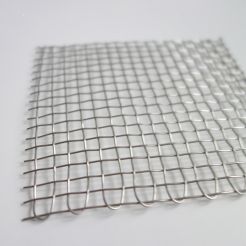

Extruder screen is a woven mesh filtration system that are welded and folded in specific shapes and sizes. The extruder screen has two configurations: single-layer and multi-layer, which can remove impurities from molten plastics. And the layer configuration of micron grading can be customized to be the materials filtration level. When choosing the specifications of the extruder screen, you need to consider factors such as pressure requirements, the characteristics of the materials used, and the required purification level. A mesh size that is too fine may achieve the required purification level, but it may cause damage to your device due to pressure levels. A large mesh size may allow for sufficient flow, but it can also allow pollutants to enter the final product.

Most extruder screens seen in the plastic industry are typically 20-150 mesh square mesh fabrics made of stainless steel to prevent corrosion/contact corrosion. In order to prevent product failure, plastic extrusion manufacturers must use sufficient filtering media during the plastic extrusion process. This is where the extruder screen comes into play. Using incorrect specifications can hinder the production speed of cleaning materials, as specifications can affect the temperature of the melt and the pressure in the system.

Wire mesh extruder screens provide distinct advantages compared to other filter media. Their durability and longevity allow them to endure the high temperatures and pressures typical in extrusion processes. These screens are also reusable after cleaning, offering a cost-efficient option for extended use. In the plastics and rubber processing industries, wire mesh extruder screens are a dependable and efficient method for filtering molten materials. They contribute to the quality and uniformity of the final product, helping to minimize defects and inconsistencies due to impurities and contaminants.

Single Layer Extruder Screen

Dashang Wire Mesh could offer a variety of wire mesh screen with single layer including Dutch Woven mesh material made of carbon steel or stainless steel.

When should you use a single layer screen? Well, the answer is ultimately determined by the material and particles you’re filtering.For instance, if you are filtering a liquid with contaminant particles of variating sizes, you may benefit from using a multi-layer as the larger contaminants would potentially damage the mesh and significantly reduce its accuracy. On the other hand, you are filtering a liquid with minimal non-abrasive impurities or attempting to extract a filter cake, a single layer configuration may be suitable for you.

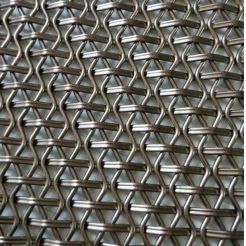

Spot Weld Packs

We have the ability to create any mesh pack and weld them in sequence to create strength and consistency in your filtration process.

Aluminum Bound Screen Packs

Framed Packs have a seamless frame of dead-soft aluminum surrounding the screens. This provides for a better seal at the edge of the breaker plate. Frames can be customized to your exact requriements.

Dashang Wire mesh offer aluminum bound to multi-layer screens, increasing rigidity for better protection in high pressure processes.

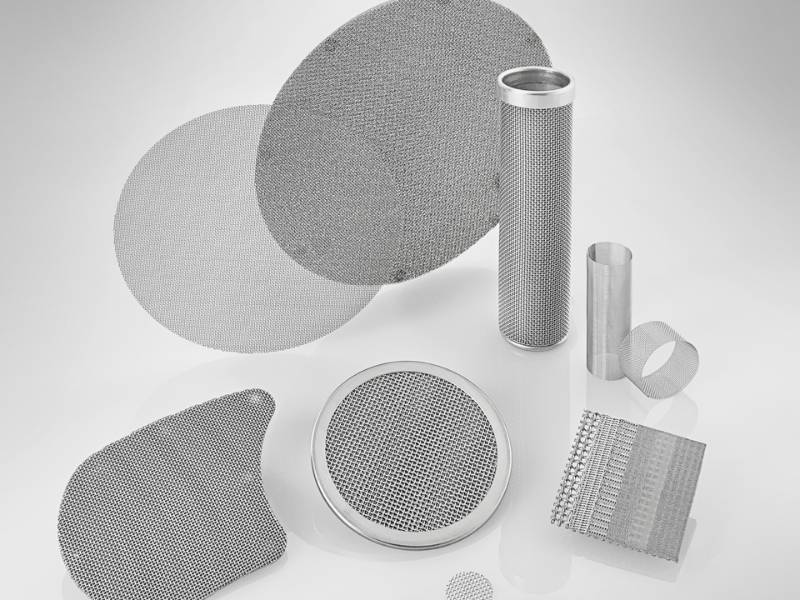

Multi-layer Cylinder Filter Tubes

Dashang Wire mesh makes cylinder screen pack elements to-order, with welded seams and ends or seam welds only, in a range of diameters and lengths. We can provide a variety of mesh types to meet your process requirements. We manufacture screens for the plastic film industry.

Special Shapes Filter Screen

Dashang Wire mesh offers round, eliptical, rectangle, annular or rings, and other special shapes for customized.

Screen Changer Belts

Continuous belt screens used with screen changers allows extruders to run continuously. We provide the quality screens to achieve peak productivity.