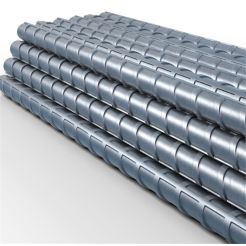

S31805/253Ma Stainless Steel Pipe

S31805/253Ma Stainless Steel Pipe

Product Description

253MA UNS S31805 W.Nr 1.4835 SS2368 Seamless Pipe

253MA stainless steel is your fortress against extreme temperatures. Engineered with a blend of chromium, nickel, and nitrogen, this austenitic alloy boasts exceptional heat resistance. 253Ma stainless steel pipe can confidently tackle high-temperature environments, offering reliable performance even at temperatures soaring up to a staggering 2000°F (1093°C).

Alloy 253Ma Chemical Composition

|

% |

Ni |

Cr |

Fe |

Mn |

C |

Si |

S |

P |

N |

Ce |

|

Min |

10.0 |

20.0 |

balance |

|

0.05 |

1.4 |

|

|

0.12 |

0.03 |

|

Max |

12.0 |

22.0 |

1.0 |

0.12 |

2.5 |

0.015 |

0.045 |

0.2 |

0.08 |

UNS S31805 Physical Constants:

|

Density |

7.8 Mg/m³ |

|

Melting Range |

1371-1432 ℃ |

253Ma pipe advantages:

1. High Creep Strength: Your assurance of durability under high-stress conditions.

2. Isothermal and Cyclic Oxidation Resistance: 253Ma pipe stands strong against the harshest oxidation challenges.

3. Combustion Gas Resistance: Defends against corrosive gases with remarkable efficiency.

4. Weldability: Easily adapted for various fabrication needs.

5. Outstanding Oxidation Resistance: Withstands extreme temperatures up to 2000°F.

6. Exceptional Creep-Rupture Strength: Comparable to premium nickel base alloys.

UNS S31805 Mechanical Properties

|

Grade |

Tensile Strength, min, (MPa) |

Yield Strength, min, (MPa) |

Elongation in 2 in. or 50mm, min, % |

Hardness, max HB |

|

S31805 |

650-850 |

310 |

40 |

210 |

253Ma pipe applications:

253MA stainless steel pipe finds its place in a multitude of industries where strength and heat resistance are paramount.

1. Oil and Gas Industry: Ideal for offshore and onshore applications.

2. Petrochemical Industry: Safeguard critical equipment in chemical processing.

3. Power Plant Industry: Ensure uninterrupted power generation.

4. Pharmaceuticals Industry: Maintain product quality and safety.

5. Refining Industry: Withstand the harsh conditions of refining processes.