Aluminium Casting Fiberglass Filtration Filter Pouch

Cangchen is specialized in producing fiberglass filter bags, our products are very popular, if you are interested in our products, please contact us as soon as possible.

Product Description

Fiberglass Filtration Pouch is weaved through special process, its withstand temperature up to 1000 °C.

Fiberglass Bag Filter Main Function:

Apply to filter and evenly distribute molten aluminum in molds.

Three Main Features:

● New environmental protection material, does not burn during whole use process, no harm to human body.

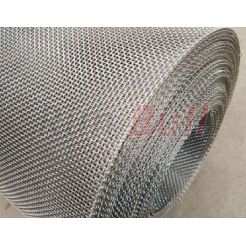

● Advanced production equipment, warp and weft standard for base cloth, high temperature resistant coating mesh uniform, the finished product is exquisitely made without burrs.

● Both sides of the bag adopt square hole fixing device technology, more convenient operation and improve the working rate.

How To Use the Fiberglass Filter Bags:

● Click here to get more introduction of user manual.

Fiberglass filter bags are bags made from fiberglass fabric that are used to filter liquids, gases, or fumes in industrial and commercial processes. Aluminium Casting Fiberglass Filtration Filter Baskets are commonly used in a variety of industries, including chemical processing, pharmaceutical manufacturing, food and beverage production, and power generation.

Fiberglass filter bags are made from a woven or non-woven fabric that is coated with a resin to make it resistant to heat, chemicals, and other environmental factors. The fibers in the fabric are extremely fine, which allows them to effectively filter out contaminants, such as dust, particles, and liquid droplets, from the air or liquid being processed.Click For More.

Fiberglass Bags Parameters are shown in the following chart:

| Type | Fiberglass Filtration Pouch/Bag/Basket For Aluminum |

| Work Temperature | ≤1000℃ |

| Melting Point | 1100℃ |

| Color | White, Brown and Yellow |

| Specifications | 5mesh, 7mesh, 8mesh, 9mesh, 10mesh, 12mesh, 14mesh, 16mesh, 18mesh, 20mesh, 25mesh, and special specifications can be customized. |

| Application | Filter molten aluminum and aluminium alloy in molds, Distribute evenly molten aluminum in molds. |

| Work Time: | 150minutes. |

| Tensile Strength | 8Kgs |

| OEM | Logo, Size and Shape of fiberglass filter bag, according to customer's requirement, and also drawing or samples. |

| Certificate | ISO9001:2015 |

If you want to customize foundry filtration products for your own brands or purchase for your projects, please contact us here.

Fiberglass Filter Bag Functions:

1. Helps to reduce the turbulence of metal flow and improve the temperature distribution throughout the mold volume.

2. Filter the molten metal and decrease in non-metallic inclusions and oxide films in the liquid metal.

3. Comparing to other filter bags, Filtration Filter Basket does not affect the component of aluminum alloy, and with good filtration effect, high temperature resistance, high strength, excellent acid and alkali resistance, non-stick aluminum, non-slagging, non-peeling, as well as easy installation.

4. Fiberglass mesh filter improves mechanical quality of aluminum casting product.

5. Improve the hardness of aluminum casting product with more average surface hard and bending strength.

Fiberglass Filter Bags Main Functions:

● Filter molten aluminum in molds.

● Distribute evenly molten aluminum in molds.

Advantages To Using Fiberglass Filter Bags/Baskets:

Filtration Filter Baskets are durable and can withstand high temperatures, making them suitable for use in high-temperature processes.

Fiberglass Filter Baskets also have a high dirt retention capacity, which means they can filter a large number of contaminants before they need to be replaced.

Additionally, fiberglass filter bags are resistant to most chemicals and are easy to clean, which makes them suitable for use in a wide range of applications.

Overall, fiberglass filter bags/baskets are an effective and efficient way to filter liquids, gases, or fumes in industrial and commercial processes.

Principles of Fiberglass Bag Filter

1. The closer the placement position is to the casting cavity, the better effect is, the better reducing the probability of secondary oxidation. The location where the casting filter is usually placed in the gating system: the lower end of sprue, the runner, the inner runner, and the sprue cup.

2. The design of the gating system should be simple, and other slag blocking measures may not be considered, which can improve the utilization rate of the sand mold and the yield of the process.

3. The aluminium pouring speed cannot be controlled with an fiberglass filter bag.

4. The working area of fiberglass filter diversion bag should be 4 times to 6 times to the blocking section of the pouring system to ensure that the pouring speed is not affected.

5. Select the corresponding filtration products according to the type of casting alloy and pouring temperature, and it should not be used at excessive temperature.

6. Select the filter screen with the appropriate aperture to truly achieve the filtering effect.

Applications of Aluminium Casting Fiberglass Filtration Filter Basket:

Blast Furnace Gas Cleaning: Fiberglass filters are used to clean blast furnace gas, which is a byproduct of steel production. They effectively remove particulate matter and other impurities, improving the quality of the gas.

Continuous Casting Cooling: Fiberglass filters are used in the continuous casting process to remove particulate matter from the cooling water. This helps to maintain a clean and efficient casting process, ensuring high-quality steel production.

Sinter Plant Dust Collection: Fiberglass filters are used to capture dust generated in the sintering process, which is an essential step in the production of iron. By removing the dust, fiberglass filters help to maintain a clean and safe working environment.

Steel Pickling: Fiberglass filters are used to clean the acid fumes generated during the pickling process, which involves removing impurities from the surface of steel. Fiberglass filters effectively remove these fumes, improving air quality in the working environment.