Wave Washer, Wave Springs

HEGONG is a professional Wave Spring Manufacturer and wave spring washer supplier in China.

Product Description

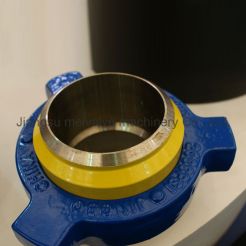

HEGONG is a professional Wave Spring Manufacturer and wave spring washer supplier in China. Wave Washer has a curvilinear shape and can be made from different raw materials – spring steel, stainless steel, and copper. The wave design of the wave washer counterbalances for the spring force and this is done by deflecting the load and acting as a spring. Wave washer is a preload between two surfaces. HEGONG, as a leading Wave Spring Manufacturer, is trying efforts to provide the best quality wave washer to give long life support to your equipment.

Wave Washer Manufacturer is a precise elastic element, which is suitable for mounting in the parts with limited installation space and stiffness requirements that other elastic elements cannot meet. Due to its unique structural form, the total height and working height of the wave spring are lower than traditional elastic elements, so it can reduce the space size of the parts and the overall cost of the product, and has an excellent performance.

Due to its unique processing technology, our wave washer manufacturer can meet various requirement about mechanical properties and fatigue life by adjusting design parameters. We can also customize wave washer and wave spring of any structure types with an outer diameter of 5mm-200mm.

Types Of Wave Spring/Wave Washer Manufacturer

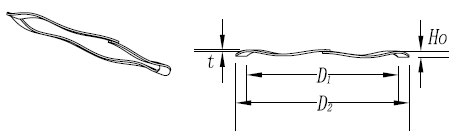

● Single-Turn Wave Spring Manufacturer

This wave washer design contains a single wave in it. Single-turn wave washers should be separated by a shim to produce a crest-to-crest wave spring.

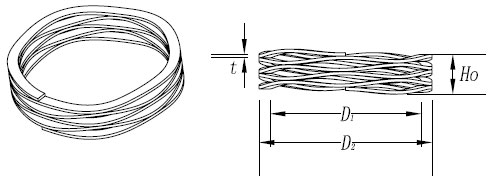

● Multi-Turn Wave Spring Manufacturer

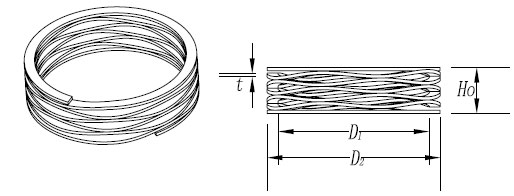

Multi-turn wave washers are good to be used to minimize the use of axial space and are suitable for applications needing large deflections and a small spring rate.

● Nested Wave Spring Manufacturer

Nested wave washers are suitable for situations with a need for high and accurate spring force.

Dimensions And Designation

| No. | Structure Form | Drawing | Feature |

| 1 | Single-turn wave washer with partially overlapping |

|

When the wave spring of this structure continues to be deformed by force, the two ends of the lap will move closer to each other to avoid binding and breaking. |

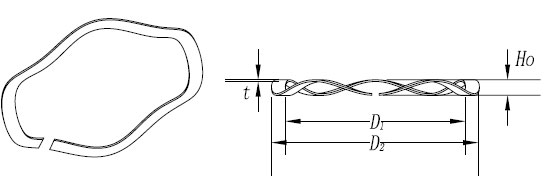

| 2 | Single-turn wave washer with gap |

|

The gap structure avoids the situation of being constrained and broken during work |

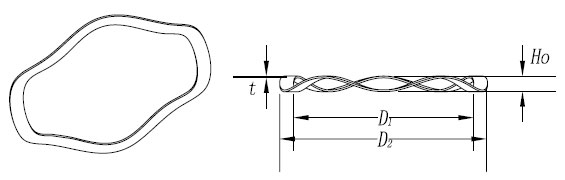

| 3 | Closed Single-turn wave washer |

|

Single turn, closed ring, the wave number is not less than 3 waves. |

| 4 | Multi-turn (Peak to Peak) wave washer |

|

With peak to peak structure, it could meet the requirements of greater deflection and higher precision. |

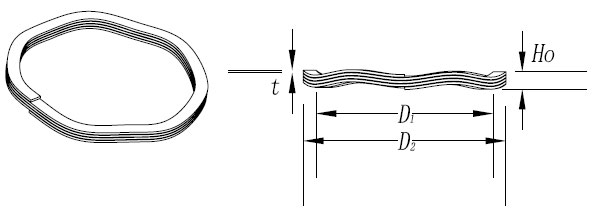

| 5 | Multi-turn (Peak to Peak) wave washer with Shim Ends |

|

The structure has a 360°contact surface, in the case of stress, the shim ends makes the force distribution more uniform under stress.The overall part structure is more stable. |

| 6 | Nested wave washer |

|

Nested wave springs have higher load force and higher precision than other elastic elements. |