Round Hole Perforated Metal

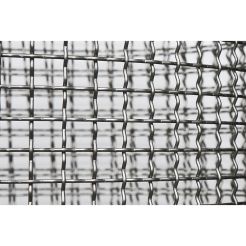

Perforated metal is a type of sheet metal that features a series of regularly spaced holes or openings across its surface. And round hole perforated metal is the most popular and widely used type. It can be manufactured in rolls or sheets, providing flexibility and ease of use in various applications.

Product Description

Perforated metal is a type of sheet metal that features a series of regularly spaced holes or openings across its surface. And round hole perforated metal is the most popular and widely used type. It can be manufactured in rolls or sheets, providing flexibility and ease of use in various applications. It is an ideal choice for applications including architectural accents, industrial screening products, and filtration solutions.

Round hole perforated metal materials

● Low carbon steel.

● Galvanized steel.

● Aluminum steel.

● Stainless steel.

● Titanium

● Monel 400

Surface treatment

PVC/powder/Epoxy coating

Round hole perforated metal patterns

We have three distinct patterns for round hole perforated materials: 60° Staggered, 45° Staggered, and Straight Line. These patterns provide different levels of openness, giving you flexibility in how your project functions and looks.

If you don't see what you need in our showcased products, reach out to our sales team. We'd love to help create a custom perforated pattern that fits your exact needs perfectly.

Specification

|

Perforated Sheet Specification – Round hole |

|||||||||||||||

|

Description |

Hole Size (mm) |

Pitch (mm) |

Open Rate |

Sheet Thickness |

|||||||||||

|

0.4 mm |

0.5 mm |

0.8 mm |

1 mm |

1.2 mm |

1.5 mm |

2 mm |

2.5 mm |

3 mm |

4 mm |

5 mm |

6 mm |

||||

|

R0.8 T2 |

0.8 |

2 |

0.15 |

* |

* |

* |

|

|

|

|

|

|

|

|

|

|

R1 T2 |

1 |

2 |

0.23 |

* |

* |

* |

* |

|

|

|

|

|

|

|

|

|

R1.2 T2.25 |

1.2 |

2.25 |

0.26 |

|

* |

* |

* |

|

|

|

|

|

|

|

|

|

R1.2 T2.5 |

1.2 |

2.5 |

0.21 |

|

* |

* |

* |

* |

|

|

|

|

|

|

|

|

R1.5 T2.75 |

1.5 |

2.75 |

0.27 |

|

* |

* |

* |

* |

|

|

|

|

|

|

|

|

R1.5 T3 |

1.5 |

3 |

0.23 |

|

* |

* |

* |

* |

|

|

|

|

|

|

|

|

R1.8 T3.5 |

1.8 |

3.5 |

0.24 |

|

* |

* |

* |

* |

* |

|

|

|

|

|

|

|

R2 T3 |

2 |

3 |

0.4 |

|

* |

* |

* |

|

|

|

|

|

|

|

|

|

R2 T3.5 |

2 |

3.5 |

0.3 |

|

* |

* |

* |

* |

* |

|

|

|

|

|

|

|

R2 T4 |

2 |

4 |

0.23 |

|

* |

* |

* |

* |

* |

* |

|

|

|

|

|

|

R2.5 T3.5 |

2.5 |

3.5 |

0.46 |

|

* |

* |

* |

|

|

|

|

|

|

|

|

|

R2.5 T4 |

2.5 |

4 |

0.35 |

|

* |

* |

* |

* |

* |

|

|

|

|

|

|

|

R2.5 T4.5 |

2.5 |

4.5 |

0.28 |

|

* |

* |

* |

* |

* |

* |

|

|

|

|

|

|

R2.5 T5 |

2.5 |

5 |

0.23 |

|

* |

* |

* |

* |

* |

* |

* |

|

|

|

|

|

R3 T5 |

3 |

5 |

0.33 |

|

* |

* |

* |

* |

* |

* |

|

|

|

|

|

|

R3 T6 |

3 |

6 |

0.23 |

|

* |

* |

* |

* |

* |

* |

* |

* |

|

|

|

|

R3.5 T5 |

3.5 |

5 |

0.44 |

|

* |

* |

* |

* |

* |

|

|

|

|

|

|

|

R4 T5 |

4 |

5 |

0.58 |

|

* |

* |

* |

|

|

|

|

|

|

|

|

|

R4 T6 |

4 |

6 |

0.4 |

|

* |

* |

* |

* |

* |

* |

|

|

|

|

|

|

R4 T8 |

4 |

8 |

0.23 |

|

* |

* |

* |

* |

* |

* |

* |

* |

|

|

|

|

R5 T7 |

5 |

7 |

0.46 |

|

* |

* |

* |

* |

* |

* |

|

|

|

|

|

|

R5 T8 |

5 |

8 |

0.35 |

|

* |

* |

* |

* |

* |

* |

* |

* |

|

|

|

|

R5 T10 |

5 |

10 |

0.23 |

|

* |

* |

* |

* |

* |

* |

* |

* |

* |

|

|

|

R5 T25 |

5 |

25 |

0.04 |

|

* |

* |

* |

* |

* |

* |

* |

* |

* |

|

|

|

R6 T8.5 |

6 |

8.5 |

0.45 |

|

* |

* |

* |

* |

* |

* |

* |

|

|

|

|

|

R6 T9 |

6 |

9 |

0.4 |

|

* |

* |

* |

* |

* |

* |

* |

* |

|

|

|

|

R6 T10 |

6 |

10 |

0.33 |

|

* |

* |

* |

* |

* |

* |

* |

* |

* |

* |

|

|

R7 T10 |

7 |

10 |

0.44 |

|

|

|

* |

* |

* |

* |

* |

* |

|

|

|

|

R8 T11 |

8 |

11 |

0.48 |

|

|

|

* |

* |

* |

* |

* |

* |

|

|

|

|

R8 T12 |

8 |

12 |

0.4 |

|

|

|

* |

* |

* |

* |

* |

* |

* |

* |

|

|

R8 T15 |

8 |

15 |

0.26 |

|

|

|

* |

* |

* |

* |

* |

* |

* |

* |

* |

|

R10 T13 |

10 |

13 |

0.54 |

|

|

|

* |

* |

* |

* |

* |

* |

* |

* |

|

|

R10 T14 |

10 |

14 |

0.46 |

|

|

|

* |

* |

* |

* |

* |

* |

* |

* |

|

|

R10 T15 |

10 |

15 |

0.4 |

|

|

|

* |

* |

* |

* |

* |

* |

* |

* |

* |

|

R10 T18 |

10 |

18 |

0.28 |

|

|

|

* |

* |

* |

* |

* |

* |

* |

* |

* |

|

R12 T16 |

12 |

16 |

0.51 |

|

|

|

* |

* |

* |

* |

* |

* |

* |

* |

|

|

R12 T17 |

12 |

17 |

0.45 |

|

|

|

* |

* |

* |

* |

* |

* |

* |

* |

* |

|

R15 T20 |

15 |

20 |

0.51 |

|

|

|

* |

* |

* |

* |

* |

* |

* |

* |

* |

|

R15 T21 |

15 |

21 |

0.46 |

|

|

|

* |

* |

* |

* |

* |

* |

* |

* |

* |

|

R20 T25 |

20 |

25 |

0.58 |

|

|

|

* |

* |

* |

* |

* |

* |

* |

* |

* |

|

R20 T27 |

20 |

27 |

0.5 |

|

|

|

* |

* |

* |

* |

* |

* |

* |

* |

* |

|

R20 T28 |

20 |

28 |

0.46 |

|

|

|

* |

* |

* |

* |

* |

* |

* |

* |

* |

|

R20 T30 |

20 |

30 |

0.4 |

|

|

|

* |

* |

* |

* |

* |

* |

* |

* |

* |

|

R25 T34 |

25 |

34 |

0.49 |

|

|

|

* |

* |

* |

* |

* |

* |

* |

* |

* |

Application

Today, the round hole perforated metalhas been applied by designers in various fields, from industrial filters, noise barriers to building interior decoration, and facade cladding, perforated fences, etc.

Applications for round perforated sheets include:

● Cladding and ceiling panels.

● Sunshade and sunscreen.

● Filter sheets for grain sieving, sandstone, kitchen garbage.

● Filter tube, inner/outer supporting layer of various filters.

● Decorative banister.

● Protective fences of overpasses and machine equipment.

● Balcony and balustrade panels.

● Ventilation sheets, such as air condition grills.

Email: inquiry@chinafiltermesh.com

Mob.: +86 157 3280 5807

WeChat: +86 157 3280 5807

Whatsapp: +8615732805807

Add.: South industrial zone, Anping, Hebei, China