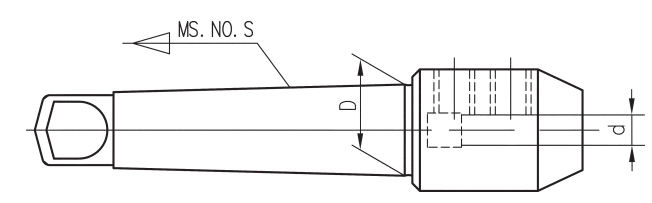

Morse Taper End Mill Holder

The Morse Taper End Mill Holder is a specialized tool holder used in machining operations to securely hold end mills with Morse Taper shanks. This holder provides a reliable and accurate connection between the cutting tool and the machine spindle, ensuring precise cutting performance.

Product Description

Products Description

MT2~MT6

d from 4mm to 63mm

A Morse Taper End Mill Holder is a tool holder designed to hold end mills with Morse Taper shanks. It is commonly used in milling machines to securely grip the end mill for precise and accurate cutting.

The Morse Taper End Mill Holder has a tapered shank that fits into the spindle of the milling machine. It is held in place by friction, which allows for easy and quick tool changes. The opposite end of the holder has a collet chuck that securely grips the Morse Taper shank of the end mill.

When using a Morse Taper End Mill Holder, it's important to ensure that both the holder and the end mill are clean and free from damage. The collet chuck should be tightened properly to ensure a secure grip on the Morse Taper shank. Proper tool alignment and concentricity should be maintained to ensure accurate and efficient cutting.

Morse Taper End Mill Holders are available in various sizes to accommodate different end mill shank sizes and machine spindles. They are commonly used in milling operations that require precise, high-speed cutting such as in manufacturing or prototyping applications.

Understanding Morse Taper

Before we explore the Morse Taper End Mill Holder, let's have a brief understanding of the Morse Taper itself. Morse Taper is a standardized system for tool shanks and machine spindles, ensuring compatibility and interchangeability. It consists of a tapered shank with a male end and a corresponding female taper in the machine spindle.

The Morse Taper system is designated by a number, such as Morse Taper 1 (MT1), Morse Taper 2 (MT2), and so on, indicating the size and dimensions of the taper.

Features and Benefits of the Morse Taper End Mill Holder

The Morse Taper End Mill Holder offers numerous features and benefits that contribute to its effectiveness in precision milling applications.

★Tapered Design: The Morse Taper End Mill Holder features a tapered shank that matches the corresponding Morse Taper size of the milling machine spindle. This design ensures a precise and secure fit, minimizing runout and maximizing tool stability during milling operations.

★Excellent Tool Holding: By utilizing the self-locking mechanism of the Morse Taper, the holder provides exceptional tool holding capabilities. It prevents tool slippage or movement during milling, enhancing the accuracy and repeatability of the machining process.

★Rigid Connection: The Morse Taper End Mill Holder establishes a rigid connection between the milling machine spindle and the end mill. This rigidity minimizes vibrations, reduces chatter, and improves overall surface finish, especially when working with high-speed or heavy-duty milling applications.

★Versatility: The Morse Taper system is widely adopted in milling machines, making the Morse Taper End Mill Holder compatible with various machines and spindles. It offers versatility and ease of use, allowing machinists to interchange different end mills quickly and efficiently.

★Ease of Installation: Installing an end mill in a Morse Taper End Mill Holder is a straightforward process. Machinists need to insert the end mill into the holder's bore, ensuring a snug fit, and secure it with a drawbar or a locking mechanism provided by the milling machine.

★Size Availability: Morse Taper End Mill Holders come in different sizes, ranging from Morse Taper #1 to Morse Taper #6, catering to a wide range of milling machine spindles and end mill diameters. See Our Products.

Applications of the Morse Taper End Mill Holder

The Morse Taper End Mill Holder finds extensive use in various precision milling applications, including:

◆Face milling

◆Profile milling

◆Slot milling

◆Contour milling

◆Chamfering

◆Drilling

◆Keyway cutting

◆Thread milling

Its versatility and ability to provide a secure tool-holding platform make it suitable for a broad range of milling operations across different industries, such as automotive, aerospace, mold-making, and general machining.

The Morse Taper End Mill Holder stands as an essential tool holder in precision milling operations. With its tapered design, excellent tool-holding capabilities, rigid connection, and versatility, it plays a crucial role in ensuring accurate and efficient milling processes. By utilizing the Morse Taper system, machinists can achieve enhanced precision, reduce tool runout, and produce high-quality machined components.