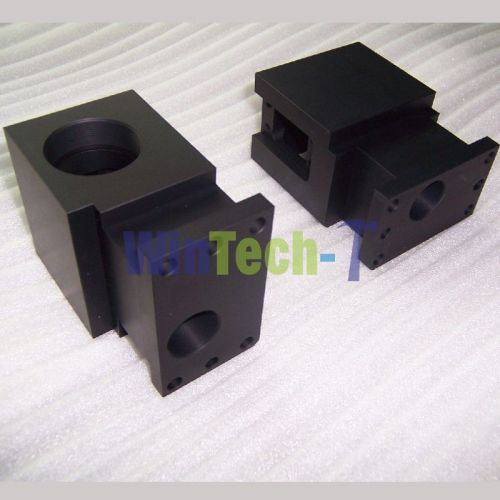

cnc turned parts manufacturer

Product Description

https://www.wintech-t.com/productstags/cnc-turned-parts-manufacturer.html

What is CNC turning and how it works

CNC turning services are a specific type of CNC machining process that involves material removal.

In CNC turning, the workpiece is held in a chuck and rotated while a turning tool is fed into the workpiece to cut away material until the desired custom CNC turned part is created.

CNC turning works on the same principle as a lathe and utilizes one of the most traditional forms of manufacturing.

High accuracy is guaranteed with the assistance of computer numerical control (CNC).

For CNC lathe service, feeds are measured in inches per revolution (ipr) or millimeters per revolution (mpr).

CNC turning is ideally suited for machining cylindrical workpieces such as shafts, disks and bushings (although it can also be used to machine square or hexagonal parts).

Features of CNC machining

Compared to traditional manual machining, CNC machine tools, the core part of CNC lathe services, are favored for the following unique features and unparalleled advantages:

High accuracy and quality

Constant quality standards throughout the manufacturing process

Multi-coordinate simultaneous operations possible

Ability to handle custom CNC turned parts with complex shapes

Easy part design changes by simply updating the CNC program

High efficiency (3-5 times more efficient than conventional machines)

Automation reduces labor and time consumption

For more information, please visit our website.