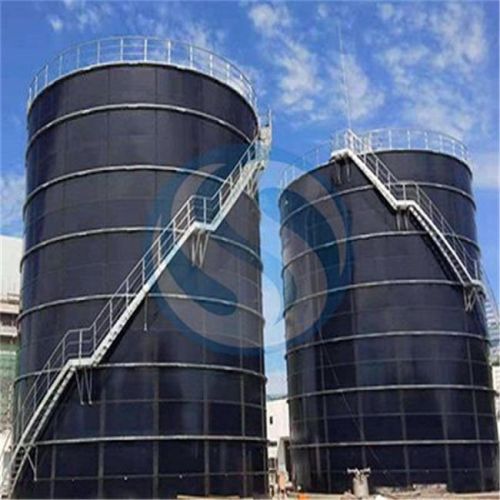

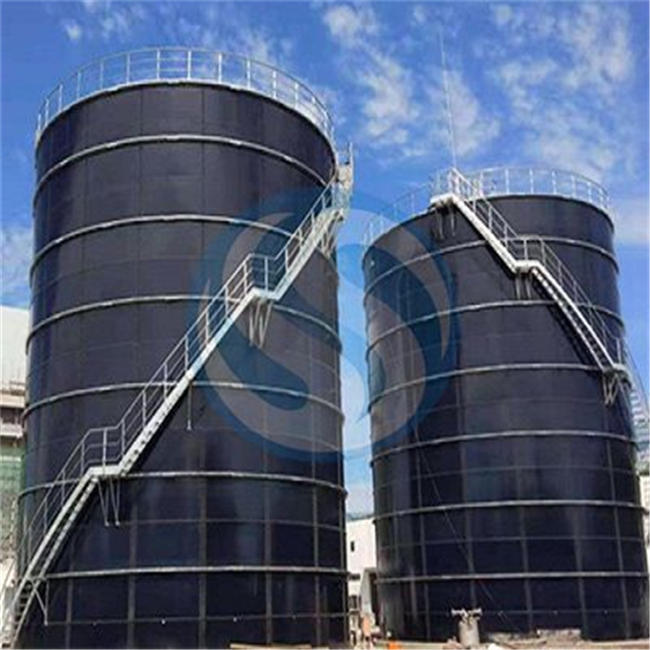

GFS Tanks with UASB Reactor

GFS Tanks with UASB Reactor

Product Description

UASB Reactor Tanks

The upflow anaerobic sludge blanket reactor (UASB) is a single tank process. Wastewater enters the reactor from the bottom, and flows upward. A suspended sludge blanket filters and treats the wastewater as the wastewater flows through it.

Technical Features of UASB Reactor Tanks

high volume load, simple equipment, easy operation, low cost, easy management, not easy to block.

Application of UASB Reactor Tanks

Scope of application: papermaking, food processing, wine brewing, landfill leachate, pharmaceutical and chemical wastewater treatment. Key design: water distribution design, three-phase separator design.

Specification of UASB Reactor Tanks

|

Coating color |

dark blue, dark green , white, and customized |

|

Standard steel plate size |

effective size 2400mm x 1200mm |

|

Steel plates thickness |

3mm - 12mm, depends on the diameter & height |

|

Coating thickness |

0.25mm - 0.4mm, two coating internal and external |

|

Acid and alkalinity proof |

standard coating suits for PH3 - PH11, special coating suits for PH1 - PH14 |

|

Adhesion |

3,450N/cm |

|

Elastic |

same as steel sheet, around 500KN/mm |

|

Hardness |

6.0 Mohs |

|

Service life |

>30 years |

|

Spark test |

>1500 V |

|

Permeability |

gas and liquid impermeable |

|

Features |

smooth, glossy, inert, anti-adhesion, and easy to clean/ maintain |

|

Corrosion resistance |

Excellent corrosion resistance for waste water salt water, sea water, high sulfur crude oil, salt fox, organic and inorganic compounds |

Advantages of UASB Reactor Glass-Fused-to-Steel Tanks

UASB consists of three parts: sludge reaction zone, gas-liquid-solid three-phase separator (including sedimentation zone) and gas chamber. Compared with other types of anaerobic reactors, it has the following advantages:

• There is a lot of biomass in the sludge bed, and the equivalent concentration can reach 20 ~ 30g / L ~ (- 1).

• The rate of volume load is high. Under the condition of medium temperature fermentation, it can reach about 5kgCOD/ (m ³d) or even as high as 10~20kgCOD/ (m³d). The hydraulic retention time in the reactor is short, so the required pool capacity is greatly reduced.

• The equipment is simple and convenient in operation, and there is no need to set up sedimentation tank and sludge reflux. The device does not need filling and mechanical stirring device in the reaction zone, the cost is relatively low, it is easy to manage, and there is no blockage.

Operation Principle of UASB Reactor Tanks

Waste water came into UASB from bottom up through the sludge zone, sludge and sewage touch each other and make anaerobic reaction to produce biogas, then rise to the top of the three-phase separator to achieve gas, solid, liquid separation. UASB can decompose more than 80% of organic pollutants and complete anaerobic reaction.

Wansheng is professional in manufacturer and supplier of GFS tanks to global markets. If you're looking for UASB reactor tanks or tank with upflow anaerobic sludge blanket reactor, please don't hesitate to contact us for more technical specification.