CBT-16 Razor Wire

Diameter of the circle in transport mode, mm: not less than 1100 ±20 Diameter of the main wire, mm: 2.80-3.0 ± 0.05

Product Description

• Diameter of the circle in transport mode, mm: not less than 1100 ±20

• Diameter of the circle in working mode, mm: not less than 900

• Number of connection points on the circle (number of brackets): 7

• Number of turns in a coil not less than: not less than 100

• Diameter of the main wire, mm: 2.80-3.0 ± 0.05

• Recommended stretching length: 20 m

• Maximum stretching length: 25 m

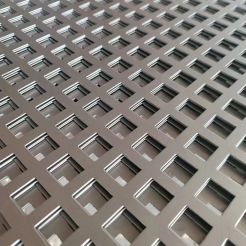

• Shape of the barbed tape blade: Aggressive, the radius of rounding of the blade base on

the barbed tape

• Weight of the coil: up to 32-35 kg

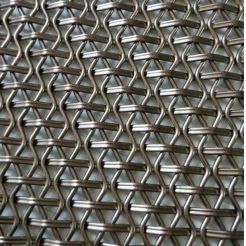

• Connecting brackets: made of galvanized steel EN 10346 with a width of not less than 10

mm and a thickness of not less than 1.5 mm

• Length of the bracket: not less than 45 mm

• Zinc coating of the bracket with a density: not less than 140 g/m2

• Material of the tape (Cutting blades): Made of carbon galvanized steel EN 10346 with a

thickness of 0.5-0.55 mm

• Length of the blades of the barbed tape: 16-17 mm

• Width of the barbed tape: not less than 19 mm

• Width of the middle strip of the barbed tape for wire crimping: not less than 7.5 mm

• Tooth pitch of the barbed tape: not more than – 30 mm

• Zinc coating density of the barbed tape: not less than 140 g/m2

• Standard of the zinc wire: according to EN 50189 (GOST 9850-72), or EN 10244-2 (GOST

7372-79) with a coating density of not less than 80 g/mm², hot-dip galvanizing (ESEN-

10264-2 (DIN 48200 or DIN 2078))

• Temporary resistance to rupture force: Not less than 1600N/mm2

Contact Us

Email: zhuocui@zc-mesh.com

Email: sales@zc-wiremesh.com

Mob.: +86 186 3188 5525

Tel.: +86 318 7536 830

Fax: +86 318 7989 906

WeChat: +86 18631885525

Whatsapp: +8618631885525

Add.: No.15, Jingsan Road, Industrial Zone, Anping, Hebei, China