Cotton Straw Briquetting Machine

Cotton Straw Briquetting Machine

Product Description

Cotton Stalk Briquette Machine Produces Biomass Fuel from Cotton Stalks.

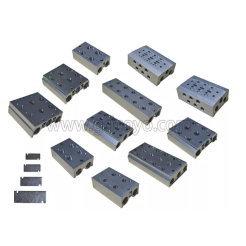

The advent of the cotton stalk briquette machine revolutionized the utilization of cotton pellets, transforming them into stalk pellets suitable for biomass fuel. This innovation has unlocked the potential to convert cotton stalks into valuable biomass pellets and briquettes, proving to be a profitable venture. Consequently, there's been a noticeable shift towards converting surplus cotton waste into a valuable and readily available resource. The finished product diagram of cotton stalk briquettes, created by the punching briquetting machine, showcases how biomass pellets and briquettes serve as a convenient fuel source for numerous manufacturers.

This process isn't limited to cotton stalks alone; it extends to various raw materials like sawdust, wheat straw, coconut shell, peanut shell, and more. These materials can be effectively utilized in the production of biomass particles. The versatility of the biomass pellets manufacturing process using a cotton straw briquetting machine has garnered interest. If you seek further insights into the intricate process of crafting biomass pellet fuel through the cotton straw briquetting machine, please feel free to reach out to us for detailed information!

Cotton Stalk Briquetting Process

The process of cotton stalk briquetting begins with the collection of cotton stalks, which are gathered and prepared for the transformation. They are meticulously reduced in size to manageable dimensions and then subjected to thorough drying, ensuring an ideal moisture content for the subsequent stages.These prepared cotton stalks are compacted using a press, a crucial step that determines the quality of the resulting briquettes. Herein lies the significance of precise control over specific parameters: moisture content, pressing temperature, and compacting pressure. These factors play pivotal roles in achieving high-quality stalk pellets.

The cotton stalk briquette machine is designed to meticulously regulate these parameters, ensuring that the moisture content, pressing temperature, and compacting pressure are precisely controlled and maintained throughout the process. This meticulous control is instrumental in producing superior-quality stalk pellets, ensuring efficiency and consistency in the production of biomass fuel from cotton stalks.

The process of converting cotton stalks into biomass fuel involves several crucial steps:

Cotton Stalk Pretreatment: Initially, a substantial amount of waste cotton stalks is gathered for the briquetting process. This involves the collection and consolidation of these stalks to prepare them for further treatment.

Crushing: The gathered cotton stalks undergo a crushing process, where they are broken down into smaller debris. This reduction in size aids in handling and processing, often involving the utilization of our crushing machinery.

Drying: Following crushing, the cotton stalks require drying. This step involves subjecting the stalks to high temperatures to eliminate moisture content. Reducing the moisture level from 40-50% to around 12% or lower is crucial. Neglecting this stage results in unusable particles for fuel production and rough surfaces on the particles.

Cotton Stalk Granulation: The pivotal phase is the briquetting process. Once the cotton stalks are adequately prepared, the pressing operation commences. Biomass briquetting equipment is utilized to shape the scattered debris into compact briquettes, creating the final product suitable for biomass fuel.

Benefits of Using Cotton Stalk Briquette Machine

Utilizing a cotton stalk briquette machine offers several advantages:

Resource Utilization: It efficiently transforms cotton stalk waste into valuable biomass fuel, effectively utilizing a previously underutilized resource.

Environmental Friendliness: The process promotes eco-friendliness by reducing agricultural waste, thereby minimizing environmental pollution.

Cost-Effective Fuel Production: Producing biomass fuel from cotton stalks proves cost-effective compared to traditional fuels, contributing to cost savings.

High-Quality Briquettes: The machine ensures the production of consistent, high-quality briquettes suitable for various heating and cooking applications.

Energy Efficiency: The resultant biomass fuel exhibits efficient combustion properties, contributing to energy efficiency during use.

Versatile Application: The produced briquettes can serve as a renewable energy source for households, industries, and commercial applications.

Reduced Emissions: When used as fuel, cotton stalk briquettes typically produce lower emissions, contributing to cleaner energy usage.